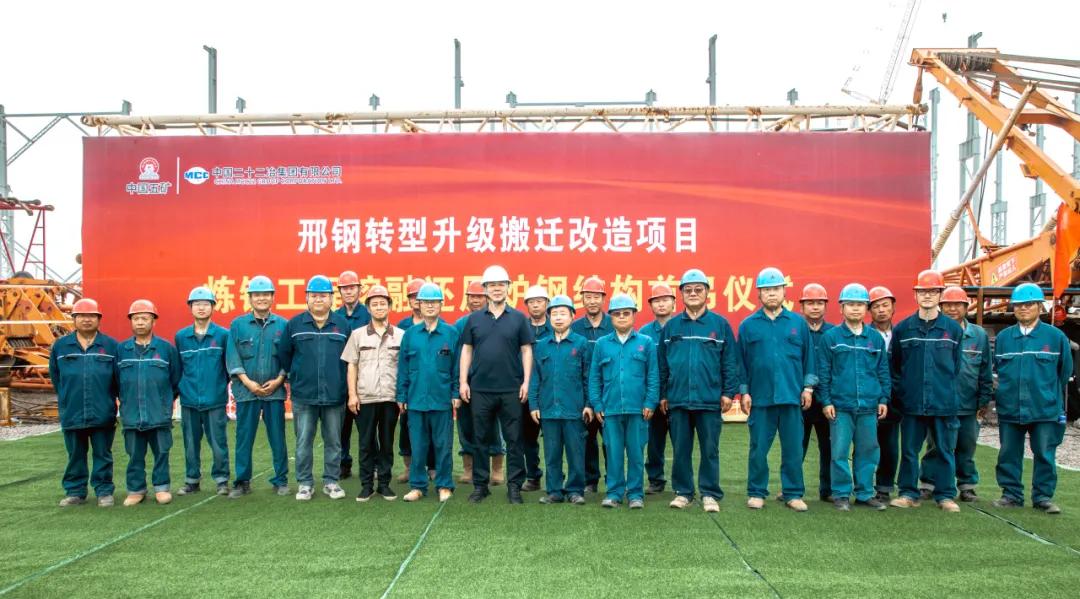

On July 8, the ironmaking zone of Xingtai Steel's relocation and transformation project witnessed a historic moment as the 46-ton steel baseplate of the smelting reduction furnace was successfully installed. The ceremony, attended by Chairman Zhang Yuming, General Manager Peng Shidan, Vice Presidents Ma Baoliang, Liu Wanchao, and Han Qinglian, along with project leaders, marked the official commencement of the furnace installation phase - a significant step in the company's green transformation strategy.

Ironmaking represents the critical control point for production costs and energy efficiency, while smelting reduction technology stands at the forefront of global metallurgical innovation, powerfully driving Xingtai Steel's project from blueprint to reality. Chairman Zhang Yuming stated that Xingtai's relocation and transformation project adopts world-leading smelting reduction ironmaking combined with electric arc furnace steelmaking - a revolutionary innovation in the steel industry. Compared with conventional processes, this technology: Eliminates pollution-intensive sintering and coking procedures. Enables direct smelting using ore and coal powder. Processes low-grade ores including high-phosphorus and vanadium-titanium magnetite. Supplies downstream manufacturers with ultra-low phosphorus hot metal. Reduces production costs while significantly lowering environmental impact.

According to the latest updates, Xingtai Steel's relocation and transformation project is advancing rapidly with the following milestones achieved in the ironmaking section:Baseplate assembly completed for #1 and #2 furnaces. Furnace shell installation currently in progress.Foundation works completed for both #1 and #2 kilns.Ready for concrete pouring.Framework column installation underway for #1 dry dedusting system.Formworks completed for AD-axis framework columns. Prepared for concrete casting.Simultaneous production of critical components including: Vaporization flues, Waste heat boilers, Pulverized coal preparation systems.The project continues to maintain strong momentum with all construction phases progressing according to schedule.